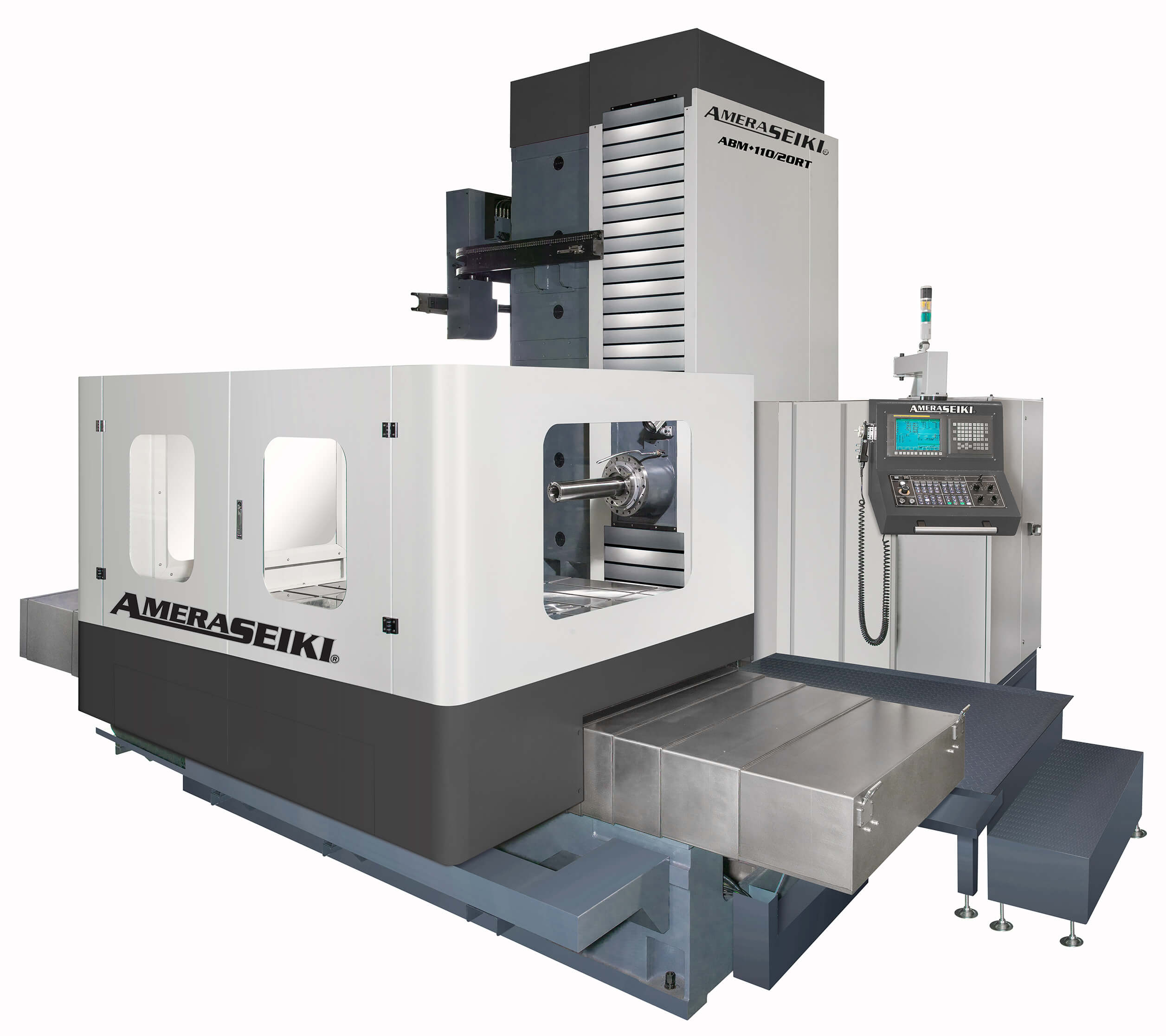

Horizontal Boring Machines

If you’re in the market for a superior quality Horizontal Boring Machine, you owe it to yourself to speak with Amera-Seiki about our ABM Series machines. We start with a heavy casting of high quality iron. All major structural parts are designed using Finite Element Analysis (FEA) software to simulate stress and strain. From there we use a combination of box ways and roller type linear ways to achieve optimal performance standards and repeatability. Our machines can handle huge weight loads on the table and the spindle head is reinforced with cage-shaped ribs to increase rigidity.

We use Fanuc controls as standard equipment and include Heidenhain linear scales on X-, Y- and Z-Axes. Our product lines include both fixed column and moving column machines with larger bar sizes than many competitors! Our ABM Series machines come standard with 40 tool ATCs, with option for 60 and even 90 tools on some models!