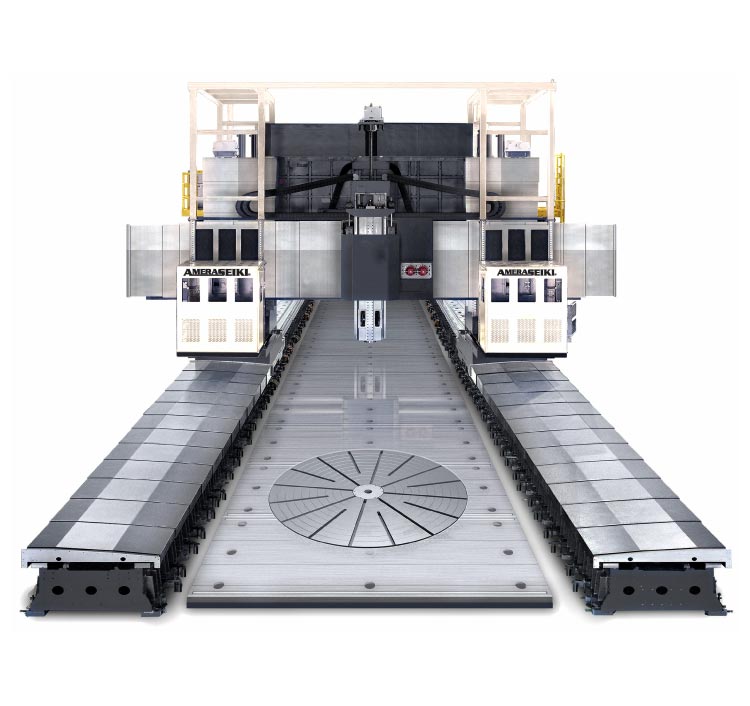

Horizontal Boring Maching

If you’re in the market for a superior quality Horizontal Boring Machine, you owe it to yourself to speak with Amera-Seiki about our ABM Series machines. We start with a heavy casting of high quality iron. All major structural parts are designed using Finite Element Analysis (FEA) software to simulate stress and strain. From there we use a combination of box ways and roller type linear ways to achieve optimal performance standards and repeatability. Our machines can handle huge weight loads on the table and the spindle head is reinforced with cage-shaped ribs to increase rigidity.

We use Fanuc controls as standard equipment and include Heidenhain linear scales on X-, Y- and Z-Axes. Our product lines include both fixed column and moving column machines with larger bar sizes than many competitors! Our ABM Series machines come standard with 40 tool ATCs, with option for 60 and even 90 tools on some models!

Amera-Seiki’s ABM Series horizontal boring machines:

- The ABM Series offers fixed and moveable column models, box and linear ways, with table sizes ranging from 1,250 x 1,250 mm up to 6,000 x 2500 mm!

- Looking for a very heavy duty boring machine? We have ABM Series machines that can handle up to 50,000 kg (55 US Ton)!

- Need a very large bar size? We have bar sizes from 4 to 6 ½ inches!

- Need machining power? Our spindle motors are 22 HP on smaller machines and 50 HP on the larger models!

Equipment To Rave About

Horizontal Machining Center Specifications

| Model | unit | ABM-110 20 IS/RS | ABM-110 20/25/32 RT | ABM-110 20/25/32/42 R | ABM-130 20/25/32/42 RT | ABM-130 32/42 R | ABM-130 32/42/52/62 RL | ABM-150 32/42/52/62 RL | ABM-110 22/26/32/42 T | ABM-110 22/26/32/42 | ABM-130 52/62 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fixed Column | Moveable Column | Moveable Column | Moveable Column | Moveable Column | Moveable Column | Moveable Column | Moveable Column | Moveable Column | Moveable Column | |||

| Table | Table Size | mm | 1250x1250x360° (opt. 0.001°) | 1600x1400x0.001° | 1400x1600x0.001° | 1600x1400x0.001° | 1800x2000x0.001° | 2200x2500x0.001° (opt. 2500x3000x0.001°) | 2000/2400/3000/4000×1400 | 2000/2400/3000/4000×1400 | 5000/6000×2500 | |

| T-Slot Size | mm | 22×7 | 24×7 | 24×7 | 24×7 | 28×9 | 28×11 (opt. 28×13) | 22 | 22 | 28 | ||

| Maximum Load | kg | 5000 | 8000 | 8000 | 8000 | 15,000 (opt. 20,000) | 30,000 (opt. 40,000) | 12,000/15,000/20,000/25,000 | 40,000/50,000 | |||

| Travel | X-Axis | mm | 2000 | 2000/2500/3200 | 2000/2500/3200/4200 | 2500/2500/3200/4200 | 3200/4200 | 3200/4200/5200/6200 | 2200/2600/3200/4200 | 5200/6200 | ||

| Y-Axis | mm | 1500 (opt. 1800) | 1800 | 2000 (opt. 2500) | 2000 (opt. 2500, 3000) | 2500 (opt. 2000, 3000) | 2500 (opt. 3000) | 1600 (opt. 1900) | 2000 (opt.2500) | 2500 (opt. 3000) | ||

| Z-Axis | mm | 1400 | 1700 | 1700 | 2000 (opt. 2500) | 2000 (opt. 2500) | 2000 (opt. 2500) | 1700 | 1700 | 2000 (opt. 2500) | ||

| W-Axis | mm | 400 (opt. 500) | 500 | 550 | 700 (opt. 900) | 700 (opt. 900) | 900 | 500 | 550 | 700 (opt. 900) | ||

| Spindle | Diameter | mm | 110 | 110 | 110 | 130 | 130 | 130 | 150 | 110 | 110 | 130 |

| Speed | RPM | 10 – 2500 (opt. 3000) | 10 – 2500 | 10 – 2000 (opt. 2500) | 10 – 2000 (opt. 2500) | 10 – 2000 (opt. 2500) | 10 – 1500 (opt. 2000) | 10 – 2500 (opt. 3000) | 10 – 2500 | 10 – 2000 (opt. 2500) | ||

| Taper | 7/24 taper ISO.50, BT 50 | |||||||||||

| Travels | Spindle Center to Table | mm | 0 – 1500 (opt. 1800) | 0 – 1800 | 0 – 2000 (opt. 2500) | 0 – 2000 (opt. 2500, 3000) | 0 – 2500 (opt. 2000,3000) | 0 – 2500 (opt. 3000) | 0 – 1600 (opt. 1900) | 0 – 2000 (opt. 2500) | 0 – 2500 (opt. 3000) | |

| Spindle Nose to Table Center | mm | 60-1860 (opt. -40 – 1860) | 0 – 2200 | 0 – 2250 | -150 – 2250 | 50 – 2750 | -50 – 2850 (opt. 3350) {50 – 2950 [3450]} | -50 – 2150 | -100 – 2150 | 200 – 2900 (opt. 0 – 2900) | ||

| Height From Ground to Table Surface | mm | 1350 | 1250 | 1250 | 1250 | 1420 | 1420 | 1420 | 1180 | 1180 | 1420 | |

| Feed Rate | Rapid Feed Rate X/Y/Z | M/min | 12 | 10 | 10 | 10 | 10 | 8/10/10 (opt. 6/10/10) | 10 | 10 | 8/10/10 | |

| Rapid Feed Rate W | M/min | 10 | 10 | 10 | 6 | 6 | 6 | 6 | 10 | 10 | 6 | |

| Minimum Setting | mm/min | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | |

| Cutting Feed Rate | mm/min | 1 – 5000 | 1 – 5000 | 1 – 5000 | 1 – 5000 | 1 – 5000 | 1 – 5000 | 1 – 5000 | 1 – 5000 | 1 – 5000 | 1 – 5000 | |

| Motor | Spindle Servo Motor, Continuous/30 min | kw | 15/18.5 (22/26) | 22/26 (30/37) | 15/18.5 (22/26) | |||||||

| Axis X/Y/Z/W/B | kw | 4/4/4/4/4(w/ B-Axis 7) | 7/4/4/4/7 | 7/7/7/4/7 | 7/7/7/4/7 | 9/7/9/4/7 | 9/7/9/4/9 | 7/4/4/4 | 7/7/7/4 | 9/7/9/4 | ||

| Lubricator Motor | kw | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| Hydraulic Pump | kw | 2.25 | 2.25 | 2.25 | 2.25 | 2.25 | 2.25 | 2.25 | 2.25 | 2.25 | 2.25 | |

| Coolant Pump | kw | 1.17 | 1.17 | 1.17 | 1.17 | 1.17 | 1.17 | 1.17 | 1.17 | 1.17 | 1.17 | |

| Chip Conveyor | kw | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Oil Cooler Pump | kw | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| ATC | Tool Capacity | pcs | 40 (opt. 60) | 40 (opt. 60) | 40 (opt.60) | 40 (opt.60) | 40 (opt. 60) | 40 (opt. 60) | 40 (opt.60) | 40 (opt. 60) | 40 (opt. 60) | 40 (opt. 60) |

| Tool Selection | Absolute | Absolute | Absolute | Absolute | Absolute | Absolute | Absolute | Absolute | Absolute | Absolute | ||

| Tool Change Time | sec | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

| Max. Tool Diameter / Length | mm | 125 (Next Empty=250) / 400 | ||||||||||

| Max. Tool Weight | kg | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| Coolant & Lubrication | Coolant Tank Volume | L | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Hydraulic Tank Volume | L | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Lubrication Tank Volumne | L | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |

| Miscellaneous | Power Required | KVA | 45 | 55 | 55 | 55 | 55 | 65 | 65 | 55 | 55 | 55 |

| Supply Air Pressure | kg/cm² | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |

| Standard Equipment | Controller: Fanuc 0i MD | Standard on All Models | ||||||||||

| Linear Scales on X/Y/Z | ||||||||||||

| Spindle Oil Cooler | ||||||||||||

| Auto. Power Off | ||||||||||||

| Hydraulic System | ||||||||||||

| Coolant System | ||||||||||||

| Lubricator System | ||||||||||||

| Alarm Lamp | ||||||||||||

| Work Lamp | ||||||||||||

| RS232 Interface | ||||||||||||

| Optional Accessories | ATC Capacity: 60, 90 | Call For Availability on Your Model | ||||||||||

| Oil Mist Device | ||||||||||||

| Controllers: Fanuc, Siemens, Heidenhein | ||||||||||||

| A/C for Electrical Cabinet | ||||||||||||

| Extension Sleeve | ||||||||||||

| Coolant Through Spindle (CTTS) | ||||||||||||

| Additional Table Weight Capacity | ||||||||||||

| 90° Milling Head | ||||||||||||

| Face Milling Head | ||||||||||||

| Spindle Motor 30/37 kw | ||||||||||||

| ZF-300 Gearbox | ||||||||||||

Quality Service & Support

Our highly-trained staff is here and ready to service CNC machines. Amera-Seiki also carries an industry-leading parts inventory.

Our Services

Innovative CNC Technology

Amera-Seiki constantly evolves to provide you with the latest in machine productivity and features. We remain on the cutting edge of machine tool technology.

About Us

Explore Our Machines

Amera-Seiki has decades of experience building a large variety of CNC machines. No matter your need, we have the machine.

Our Machines