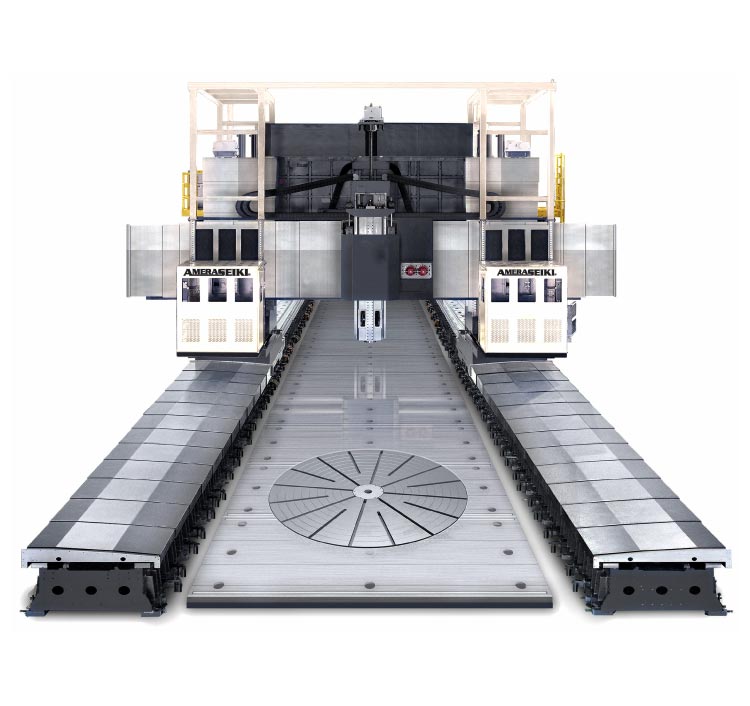

Vertical Machining Centers

Amera-Seiki started making Vertical Machining Centers in 1991. They consistently rate as top performers in their category. Our latest generation of vertical machining centers has all that you’d expect from Amera-Seiki. We have been the premium creator of all types of CNC machinery since our first machine!

Our roller-type linear guideway machines offer a wide range of speed and rigidity, while our box way models are available for your toughest applications. High torque spindle motors and servo systems assure smooth, vibration-free cuts in your hardest materials.

All of our models come standard with a fast, trouble-free arm style tool changer.

Options available include:

- Specialized coolant systems

- High speed spindle upgrades

- Fourth axis rotary tables

- Probing systems

Top Quality Vertical Machining Centers

- Choose from box ways or linear ways to get the machine that’s perfect for your needs.

- If you need power, we can offer up to 35 HP motors on our VMCs.

- With castings that are 25% heavier than similar machines from other manufacturers, our VMCs will provide superior strength for machining quality with less chatter.

- Fanuc controls are standard. We even have conversational programming available.

- Our double-nut ball screws use two sets of thrust bearings for incredible accuracy and repeatability.

- Need additional options like a fourth axis table or 1000 PSI Coolant Through Spindle (CTS)? We can assist with that as well.

Equipment To Rave About

VMC Linear Ways Specifications

| Model | Unit | AV-510L | AV-610L | AV-850L | AV-1000L | AV-1200L | AV-1300L | AV-1600L | |

|---|---|---|---|---|---|---|---|---|---|

| Travels | X-Axis | mm | 510 | 610 | 850 | 1020 | 1200 | 1300 | 1600 |

| Y-Axis | mm | 410 | 460 | 510 | 610 | 700 | |||

| Z-Axis | mm | 460 | 510 | 560 | 610 | 700 | |||

| X/Y/Z Ballscrews | mm | C3 32 | C3 40 | C3 45 | |||||

| Spindle Nose to Table Surface | mm | 130-590 | 120-630 | 150-710 | 150-760 | BT 40: 130-830 BT 50: 100-800 | |||

| Spindle Center to Column Surface | mm | 430 | 553 | 608 | 717 | 750 | |||

| Table | Table Size | mm | 600×320 | 800×450 | 1000×500 | 1200×500 | 1300×600 | 1450×700 | 1750×700 |

| T-Slot (Size/Qty./Dist.) | mm | 14x3x100 | 18x3x100 | 18x5x100 | 18x5x125 | ||||

| Max. Load on Table | kg | 300 | 400 | 500 | 1000 | 1200 | |||

| Spindle | Spindle Speed | RPM | 8000 (opt. 10K-24K) | 8000 (opt 10K-15K) | 8000 | ||||

| Taper | BT 40 / DIN 40 / CAT 40 | BT40/DIN40/CAT40 (OPT. BT50/DIN50/CAT 50) | |||||||

| Spindle Drive | Belt Driven | ||||||||

| Feed Rates | Rapid Feed Rate, X/Y/Z | M/min | 36/36/36 | 30/30/24 | |||||

| Cutting Feed Rate | mm/min | 1-10,000 | |||||||

| ATC | Tool Capacity | pcs | Genoa 12 (Armless 20, w/ Arm 20) | Genoa 16 (Armless 20, w/ Arm 24) | Genoa 20 (Armless 24, w/ Arm 32) | ||||

| Max. Tool Diameter | mm | Full=100, Next Empty=150 | |||||||

| Max. Tool Length | mm | 300 | |||||||

| Max. Tool Weight | kg | 6 | |||||||

| Power | Spindle Motor | kw (HP) | 3.5/5.5 (7.5HP) | 5.5/7.5 (10HP) | 7.5/11 (15HP) | ||||

| Axis Motors | kw | 1.5 | 2 | 3 | |||||

| Coolant | Coolant Pressure | kg/cm² | 10 | ||||||

| Coolant Pump | HP | 0.75 | |||||||

| Coolant Tank Capacity | L | 3 | |||||||

| Air & Power Supply | Air Source | kg/cm² | 6 | ||||||

| Power Supply | KVA | 15 | 20 | ||||||

| Machine | Machine Dimensions (LxWxH) | mm | 2000x2305x2460 | 2160x2435x2550 | 2900x2420x2850 | 2900x2420x2840 | 3448x2805x3044 | 3650x2915x3026 | 4050x2915x3026 |

| Machine Net Weight (approx.) | kg | 2800 | 4860 | 6880 | 6400 | 7610 | 8350 | 10,000 | |

| Machine Gross Weight (approx.) | kg | 3000 | 5060 | 7080 | 6600 | 7810 | 8550 | 10,300 | |

| Standard Features | Fanuc Controls | Included With all Models | |||||||

| Rigid Tapping | |||||||||

| RS-232 Interface | |||||||||

| Auto Power Off | |||||||||

| Auto Lubrication | |||||||||

| Halogen Work Light | |||||||||

| End of Program Light | |||||||||

| Heat Exchanger for Elec. Cabinet | |||||||||

| Full Guarding Chip Enclosure | |||||||||

| Remote Handwheel | |||||||||

| Spindle Oil Cooler | |||||||||

| Optional Accessories | High Pressure Coolant | Available With all Models | |||||||

| A/C for Elec. Cabinet | |||||||||

| Coolant Through Spindle (CTTS) | |||||||||

| Screw Type Chip Conveyor | |||||||||

| Chain Type Chip Conveyor | |||||||||

| Scraper Type Chip Conveyor | |||||||||

| Oil Skimmer | |||||||||

| Oil Through Tool Holder | |||||||||

| Oil Mist Lubrication Pump | |||||||||

| 4th Axis | |||||||||

VMC AV Series Box Way, Belt Driven Specifications

| Model | Unit | AV-510B | AV-610B | AV-850B | AV-1000B | AV-1100B | AV-1300B | AV-1600B | AV-2000B | AV-2200B | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Travel | X-Axis | mm | 510 | 610 | 850 | 1020 | 1100 | 1600 | 1600 | 2000 | 2200 |

| Y-Axis | mm | 410 | 460 | 510 | 510 | 700 | 700 | 800 | 900 | 1000 | |

| Z-Axis | mm | 460 | 510 | 560 | 560 | 610 | 710 | 800 | 800 | 800 | |

| X/Y/Z Ballscrews | mm | C3 32 | C3 40 | C3 50 | |||||||

| Spindle Nose to Table Surface | mm | 130-590 | 130-640 | 140-700 | 130-740 | 130-840 | 200-1000 | 250-1050 | |||

| Table | Table Size | mm | 600×370 | 800×450 | 1000×500 | 1200×500 | 1300×650 | 1500×650 | 1800×840 | 2200×850 | 2400×1000 |

| T-Slot (Size/Quan./Spacing) | mm | 14 / 3 / 100 | 18 / 3 / 100 | 18 / 5 / 100 | 22 / 5 / 150 | 22 / 7 / 150 | |||||

| Max. Table Load | kg | 300 | 400 | 500 | 1000 | 2200 | 2500 | 3000 | |||

| Spindle | Speed | RPM | 8000 (opt. 10K – 24K) | 8000 (opt. 10K-15K) | |||||||

| Taper | BT 40 / DIN 40 / CAT 40 | ||||||||||

| Drive System | Belt Drive | ||||||||||

| Feed Rates | Rapid Feed Rate X/Y/Z Axes | M/min | 24 / 24 / 16 | 24 / 24 / 15 | 15 / 15 / 12 | ||||||

| Cutting Feed Rate | mm/min | 1-10,000 | |||||||||

| ATC | Tool Capacity | pcs | Armless 12 (opt. 20) | Armless 16 (opt. armless 20, w/ arm 24) | Armless 20 (opt. w/ arm 24, w/ chain 32) | #40 Arm 24 (opt. w/ chain 32) | |||||

| Max. Tool Diameter | mm | Full=100, Next Empty=150 | Full=80, Next Empty=150 | ||||||||

| Max. Tool Length | mm | 300 | |||||||||

| Max. Tool Weight | kg | 6 | 7 | 7.5 | |||||||

| Motor Power | Spindle Motor | kw (HP) | 3.5/5.5 (7.5HP) | 5.5/7.5 (10HP) | 7.5/11 (15HP) | 11/15 (20HP) | |||||

| Axis Motors | kw | 1.5 | 2 | 3.5 | 3.5/7/3.5 | ||||||

| Coolant | Pressure | kg/cm² | 10 | ||||||||

| Pump Power | HP | 0.75 | |||||||||

| Tank Capacity | L | 180 | 200 | 230 | 270 | 300 | 590 | ||||

| Air & Power Supply | Air Source Pressure | kg/cm² | 6 | ||||||||

| Power | KVA | 15 | 20 | 35 | |||||||

| Machine | Dimensions (LxWxH) | mm | 2000x2305x2460 | 2160x2435x2550 | 2900x2420x2850 | 2900x2420x2840 | 3000x2825x3028 | 3200x2825x3028 | 4400x3428x3310 | 5500x3750x3310 | 6130x4200x3530 |

| Net Weight (approx.) | kg | 2800 | 4860 | 6880 | 6400 | 8660 | 9600 | 17,700 | 18,500 | 25,000 | |

| Gross Weight (approx.) | kg | 3000 | 5060 | 7080 | 6600 | 8860 | 9800 | 18,000 | 18,900 | 25,400 | |

| Standard Features | Fanuc Control | Included With All Models | |||||||||

| Rigid Tapping | |||||||||||

| Auto Power Off | |||||||||||

| Auto Lubrication | |||||||||||

| RS-232 Interface | |||||||||||

| Halogen Work Light | |||||||||||

| End of Program Light | |||||||||||

| Heat Exchanger for Elec. Cabinet | |||||||||||

| Full Guarding Chip Enclosure | |||||||||||

| Remote Handwheel | |||||||||||

| Spindle Oil Cooler | |||||||||||

| Optional Accessories | High Pressure Coolant | Available With All Models | |||||||||

| A/C for Elec. Cabinet | |||||||||||

| Coolant Through Spindle (CTTS) | |||||||||||

| Screw Type Chip Conveyor | |||||||||||

| Oil Skimmer | |||||||||||

| Chain Type Chip Conveyor | |||||||||||

| Oil Through Tool Holder | |||||||||||

| Scraper Type Chip Conveyor | |||||||||||

| Oil Mist Lubrication Pump | |||||||||||

| 4th Axis | |||||||||||

VMC AV Series Box Way, Gear Driven Specs

| Model | Unit | AV-850BG | AV-1000BG | AV-1104BG | AV-1105BG | AV-1304BG | AV-1305BG | AV-1600BG | AV-2000BG | AV-2200BG | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Travels | X-Axis | mm | 850 | 1020 | 1100 | 1300 | 1600 | 2000 | 2200 | ||

| Y-Axis | mm | 510 | 510 | 700 | 800 | 900 | 1000 | ||||

| Z-Axis | mm | 560 | 710 | 800 | |||||||

| X/Y/Z Ballscrews | mm | C3 40 | C3 50 | ||||||||

| Spindle Nose to Table Surface | mm | 140-700 | 130-740 | 130-840 | 200-1000 | 250-1050 | |||||

| Spindle Center to Column Surface | mm | 575 | 730 | 870 | 1050 | ||||||

| Table | Table Size | mm | 1000×500 | 1200×500 | 1300×650 | 1500×650 | 1800×840 | 2200×850 | 2400×1000 | ||

| T-Slot (Size/Qty./Distance) | mm | 18x5x100 | 22x5x150 | 22x7x150 | |||||||

| Max. Load on Table | kg | 500 | 1000 | 2200 | 2500 | 3000 | |||||

| Spindle | Speed | RPM | 8000 (opt. 10K-15K) | 8000 | 6000 | 8000 | 6000 | ||||

| Taper | BT 40 / DIN 40 / CAT 40 | BT 50 / DIN 50 / CAT 50 | BT 40 / DIN 40 / CAT 40 | BT 50 / DIN 50 / CAT 50 | |||||||

| Drive Type | Gear Drive | ||||||||||

| Feed Rates | Rapid Feed Rate X/Y/Z | M/min | 24/24/16 | 24/24/15 | 15/15/12 | ||||||

| Cutting Feed Rates | mm/min | 1-10,000 | |||||||||

| ATC | Tool Capacity | pcs | Armless 16 (opt. Armless 20, w/ Arm 24) | #40 Arm 24 (opt. Chain 32) | #50 Arm 24 (opt. Chain 32) | #40 Arm 24 (opt. Chain 32) | #50 Arm 24 (opt. Chain 32) | ||||

| Max. Tool Diameter | mm | Full=100, Next Empty-150 | Full=80, Next Empty=150 | Full=125, Next Empty=200 | Full=80, Next Empty=150 | Full=125, Next Empty=200 | |||||

| Max. Tool Length | mm | 300 | |||||||||

| Max. Tool Weight | kg | 7 | 15 | 7 | 15 | ||||||

| Power | Spindle Motor | kw(HP) | 5.5/7.5 (10HP) | 7.5/11 (15HP) | 11/15 (20HP) | ||||||

| Axis Motors | kw | 2 | 3.5 | 3.5/7/3.5 | |||||||

| Coolant | Pressure | kg/cm² | 10 | ||||||||

| Coolant Pump Power | HP | 0.75 | |||||||||

| Coolant Tank Capacity | L | 230 | 270 | 300 | 590 | ||||||

| Air & Power Supply | Air Source Pressure | kg/cm² | 6 | ||||||||

| Power Supply | KVA | 15 | 20 | 35 | |||||||

| Machine | Machine Dimensions LxWxH | mm | 2900x2420x2850 | 2900x2420x840 | 3000x2825x3100 | 3200x2825x3100 | 3000x2825x3100 | 3200x2825x3100 | 4400x3330x3310 | 5500x3750x3310 | 6130x4200x3530 |

| Machine Net Weight (approx.) | kg | 7080 | 6600 | 9600 | 9700 | 9800 | 9900 | 17,900 | 18,700 | 25,200 | |

| Machine Gross Weight (approx.) | kg | 7280 | 6800 | 9800 | 9900 | 10,000 | 11,000 | 18,200 | 19,100 | 25,600 | |

| Standard Features | Fanuc Control | Included with all models | |||||||||

| Rigid Tapping | |||||||||||

| Auto Power Off | |||||||||||

| Auto Lubrication | |||||||||||

| RS-232 Interface | |||||||||||

| Halogen Work Light | |||||||||||

| End of Program Light | |||||||||||

| Heat Exchanger for Elec. Cabinet | |||||||||||

| Full Guarding Chip Enclosure | |||||||||||

| Remote Handwheel | |||||||||||

| Spindle Oil Cooler | |||||||||||

| Optional Accessories | High Pressure Coolant | Included with all models | |||||||||

| A/C for Elec. Cabinet | |||||||||||

| Coolant Through Spindle (CTTS) | |||||||||||

| Screw Type Chip Conveyor | |||||||||||

| Oil Skimmer | |||||||||||

| Chain Type Chip Conveyor | |||||||||||

| Oil Through Tool Holder | |||||||||||

| Scraper Type Chip Conveyor | |||||||||||

| Oil Mist Lubrication Pump | |||||||||||

| 4th Axis | |||||||||||

Quality Service & Support

Our highly-trained staff is here and ready to service CNC machines. Amera-Seiki also carries an industry-leading parts inventory.

Our Services

Innovative CNC Technology

Amera-Seiki constantly evolves to provide you with the latest in machine productivity and features. We remain on the cutting edge of machine tool technology.

About Us

Explore Our Machines

Amera-Seiki has decades of experience building a large variety of CNC machines. No matter your need, we have the machine.

Our Machines